Manufacturing Needs of Startups: Everything You Need to Know

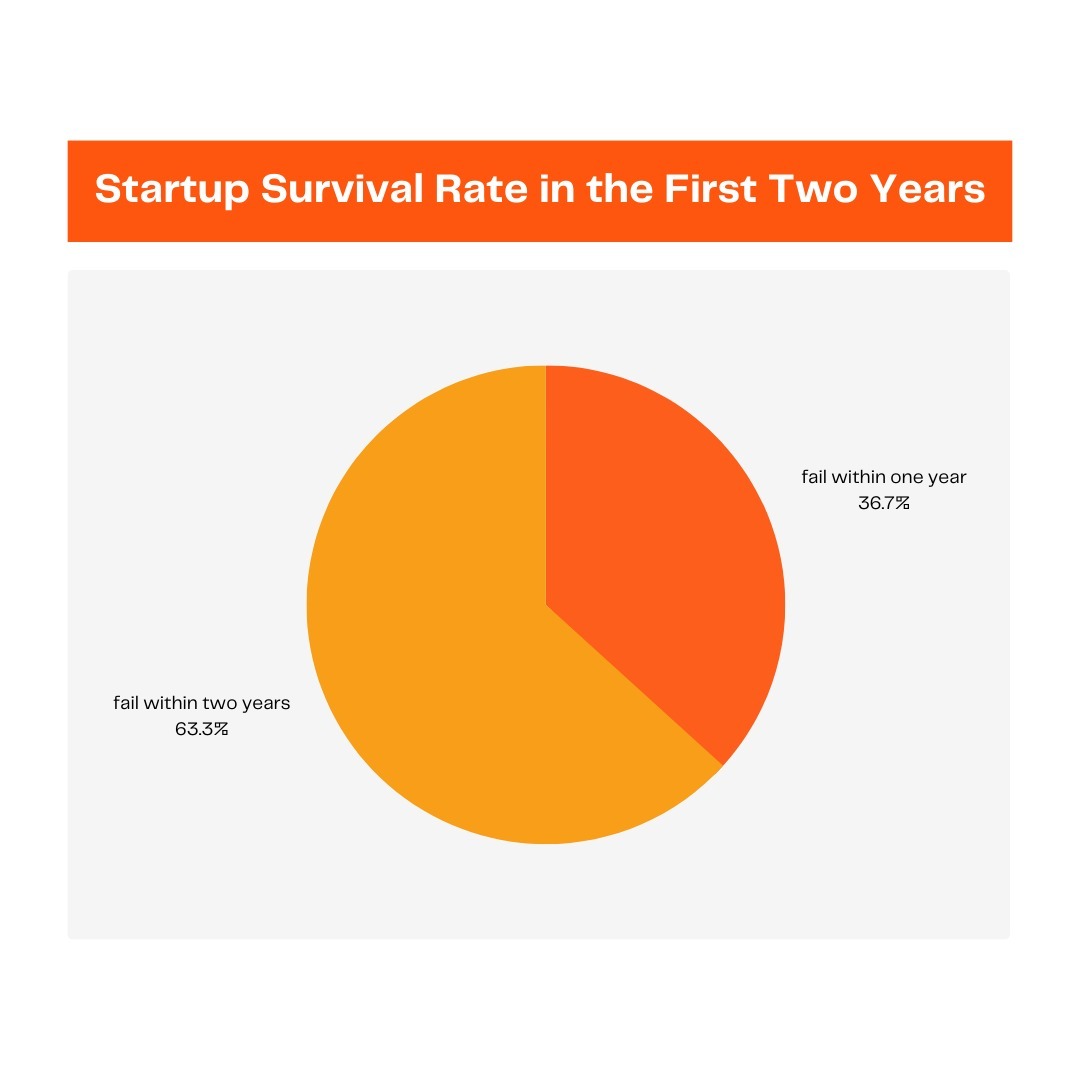

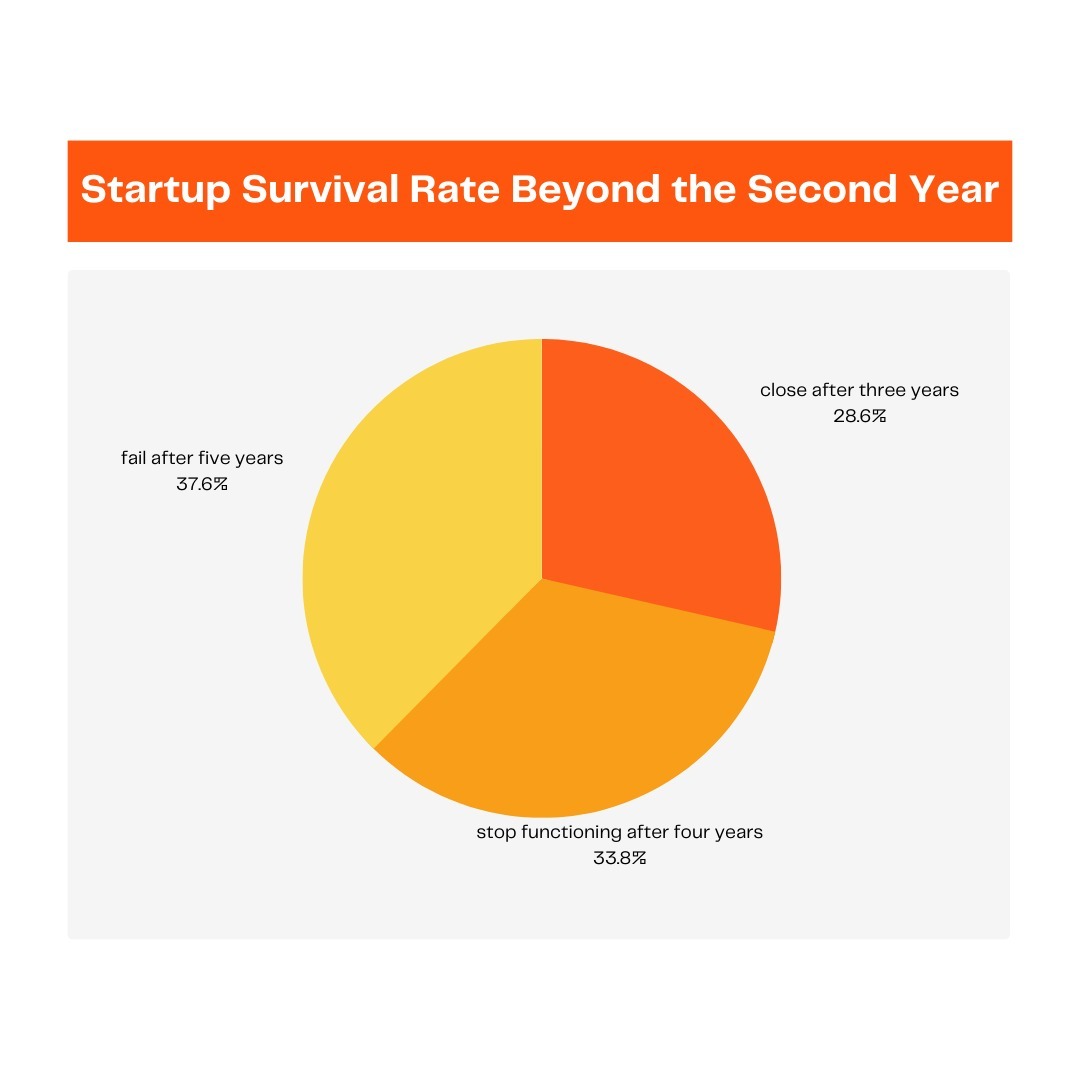

It’s not uncommon for startups to struggle during the first few years of establishment. The industry is highly competitive, and startups don’t always have the same budget, experience, equipment, or skills to work with reputable manufacturers. According to Small Business Trends, only two in five startups are profitable, and one in three will break even or continue to lose money.

Common Challenges Faced by Startups in the Industry

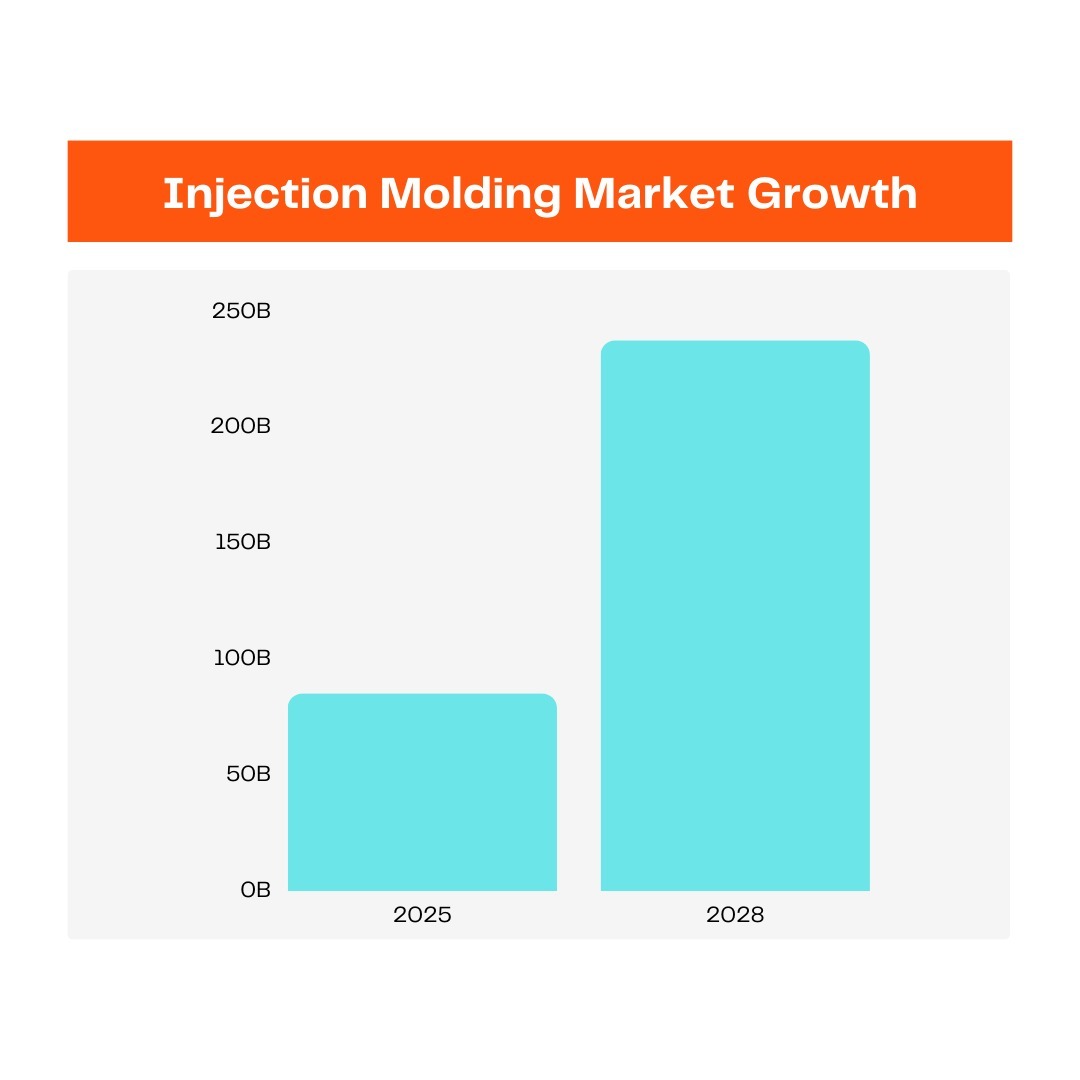

This shows that a manufacturer in the injection molding industry can help you succeed by having a proper growth and implementation strategy. Here are a few common pain points.

Lack of In-Depth Knowledge

A startup is less likely to have the same in-depth knowledge and experience as an established enterprise. Several startups tend to go for the trial-and-error approach. This increases the risk levels and may not always deliver results. Decisions made with limited knowledge of the situation and market conditions could easily backfire and lead to losses.

Several aspects come into play here. Firstly, startups may not be able to hire employees with high experience and skills due to budget and competition. Secondly, the management and decision-makers may have to rely on external factors or even luck to pull off an order or a deal. Thirdly, troubleshooting errors may take more time and disrupt the entire supply chain.

Lack of Equipment/ Machinery

Another challenge faced by startups is the lack of heavy machinery. While the unit will have enough equipment to begin production, it may not be extensive and support bulk manufacturing. Furthermore, startups cannot invest heavy amounts into the latest technology and upgrade their machines regularly.

Automation, artificial intelligence, remote supervision, etc., need a greater budget to make an impact on manufacturing. Moreover, startups may have to let go of certain orders due to a lack of support or technical know-how about how to get their parts manufactured. Founders can overestimate the manufacturing complications and choose to let go of some business opportunities.

Cost-Effectiveness and Low-Volume Manufacturing

Bulk orders are common in manufacturing. You can see manufacturers setting a minimum order limit to accept a project. But not every business needs 500 or 1000 pieces of a product. Especially in today’s world, where customers expect personalized products, one cannot simply manufacture them in large quantities. This can add more roadblocks in a startup’s Journey.

Furthermore, low-volume production is not budget-friendly for manufacturers. The resources required for the order and the end product don’t align. This leads to losses and may force the startup to shut down.

Selection of Raw Materials

Do you know that there are around 10,000 different types of plastic materials? They are used in different industries and have varying properties. For example, Polyethylene Terephthalate (PET) is a lightweight, transparent, and strong plastic used in the food packaging industry (bottles, containers, etc.). Polyvinyl Chloride (PVC) is a hard plastic with high durability and resistance to chemicals and changing weather conditions.

When manufacturing a product, it’s vital to choose the right raw materials based on the requirements, budget, quality, etc. Some plastics have similar properties but cannot be substituted or replaced. In such instances, wrong selection can affect the end product and lead to losses. Experience and industry knowledge are necessary to make the right decisions at this stage.

Experience enhances resource optimization and increases ROI

Mold Selection

It’s not enough to choose the right raw materials. It’s equally important to choose the correct mold to convert the raw material into an end product. Startups don’t always have access to necessary guidance, which makes them susceptible to picking incorrect mold.

Factors like temperature, purpose, type, design, target market, time limit, etc., should be considered when choosing the molds for injection molding. The quality of the final products depends on the mold. Also, startups cannot afford to repeatedly buy mold if they don’t last long.

Delivery Time

The manufacturing industry has a longer delivery time due to multiple stages of production, quality assurance, and packaging. Even the idle/ waiting time is high and cannot be compromised as it can affect the product quality. Generally, it takes five to six months to complete and deliver an order.

Startups cannot afford to have such lengthy delivery times as they need to accept more projects to break even and prevent losses. Effectively shortening this duration will allow the startup manufacturer to generate enough income to keep the business afloat.

Sampling

As per CBInsights, 42% of the failure rate is due to misreading the market demands. Startups cannot afford to offer extensive samples for the products they manufacture due to budget and time constraints. However, this can make it hard to cater to the changing customer demands. People no longer want to take what is available.

Injection molding is flexible and can be customized to suit varying requirements. However, a startup cannot present various samples to clients due to production constraints. Working with limited samples may not be effective in sustaining the business for long.

How to Overcome the Challenges by Partnering with Trumould

Till now, we have seen various challenges faced by startups in the manufacturing industry. Fortunately, there are solutions to every problem. Partnering with an established injection molding company is the best way to overcome these issues.

For example, Trumould is a reputed injection molding manufacturer in the US with clients from around the globe. The company offers the following to its partners:

● Access to in-depth knowledge and expert professionals with years of domain experience in the industry

● Access to the latest technology, equipment, and machinery for bulk manufacturing

● Ability to produce a product in low volumes, with no minimum limit on any order

● Talented employees with qualifications and skills to choose the correct raw materials and a wide network of reliable suppliers

● Industry-wise experience in designing and using molds based on product requirements, quality, and durability

● Shorter delivery time (of around forty to forty-five days) while guaranteeing quality and service

● Customized sampling on all orders to provide more options and greater flexibility for clients

Furthermore, Trumould has three distinctive advantages that set it apart from other injection molding companies in the global market.

Shortages are a thing of the past with the right partner at your side

Quoting Time

Trumould has developed an in-house solution to shorten the quoting time on orders. The Auto Quote Engine allows users to enter the input details and CAD image file (.STEP) to get a quote in just a few seconds. You can tweak the requirements through the intuitive interface and get different quotes without additional waiting time. Once done, you place an order directly through the same interface. No need to wait for anyone to revert with complex calculations and negotiate the price. The algorithm has been designed to include discounts for bulk orders.

Mold Making Technology – MUD Mould Technology

Master Unit Die Quick-Change (MUD) Mould Technology is a system designed to mass manufacture customized products and increase production while reducing working capital and tooling costs. It is an interchangeable modular mold base system that combines different frame types. Here, the plates can be replaced as and when necessary to customize the output without changing or restarting the entire process. This saves time, resources, raw materials, and production costs.

Experience

Trumould has years of experience in the industry and works with a multitude of clients to cater to diverse manufacturing needs. From choosing raw materials and vendors to designing the perfect mold for the project, manufacturing quality control, finishing, packaging, and delivery, the company takes special care at every step. Moreover, Trumould has a streamlined and automated process that can wrap up the mold delivery in just two to three days instead of making clients wait for weeks.

Why Look for an Injection Molding Partner rather than a Manufacturer

According to SBA, the startup failure rate is similar across all industries. However, SmallBiz Trends says that startups have been turning heavily to technology to reduce the risk of losses since 2022. Partnering with established injection molding manufacturers helps startups gain access to advanced technology and experience required to survive the competitive markets.

While startups can work on an order-to-order basis with manufacturers, collaborating with a partner offers greater benefits such as the following

Sustainability & Long-term Relationship

Sustainability has become a necessity in today’s world. However, it can be achieved when startups have an established injection molding partner to cater to their needs and complete the projects on time. For example, Trumould has a large network of suppliers and a robust supply chain, which provide the necessary backing for a business to establish itself in the market.

Continuous & Collaborative

Every business needs regular orders to ensure ROI from its investment. At the same time, managing all orders simultaneously can be stressful. Unexpected disruptions and breakdowns can lead to delays and losses. Such risks can be minimized by partnering with injection molding companies like Trumould. The company will always be there to provide assistance in effectively delivering the orders.

Guidance and Support

As discussed earlier in the post, lack of experience, guidance, and support is one of the biggest challenges for startups. This can be overcome by partnering with an injection molding company. From selecting the correct raw materials to picking up the correct mold and manufacturing versatile products, the company will provide the much-required guidance at every stage.

Decision-making

A business has to make countless decisions that affect its growth and financial condition in the short and long term. Many times, startups have to rely on limited experience, guesswork, instinct, or luck when making decisions. Partnering with an injection molding company helps make decisions based on experience and data. This reduces the risk of complications and strengthens the business position in the market.

Consistency & Quality

Imagine using a different injection molding company for each project. Wouldn’t it affect the quality and consistency of the output? This will, in turn, affect the startup’s relationship with clients and end-users. However, by having the same partner, manufacturers can provide consistent results and adhere to the quality standards in the industry.

Benchmarking

Startups should plan for the long term if they want to continue making an impact in the market. Don’t think only about a single project but consider how the project and client can boost the business. Consider how many more projects can be won by delivering satisfying results to the client. Over time, startup manufacturers can benchmark their quality practices and successfully complete audits to get certifications from authorities. This helps the business to easily enter more markets.

Final Words

Startups can increase their success rate and strengthen their market position by understanding the various challenges and ways to overcome them. Finding the right injection molding partner is the key to success.

Trumould is a reputed, reliable, and affordable injection molding company offering versatile services in the global market. The company works with businesses from several industries, ranging from automotive to agriculture, toy manufacturing, and many more.

Reach out to us at app.trumould.com to gain a long-term collaborative partner for all your injection molding needs.

Reference Links:

https://www.embroker.com/blog/startup-statistics/

https://www.mordorintelligence.com/industry-reports/plastics-injection-molding-market

https://www.adroll.com/blog/getting-it-built-how-startups-choose-a-manufacturer

https://www.kwixand.com/post/common-manufacturing-challenges-for-smes-how-to-overcome-them