Innovating the Driving Experience

Automotive Injection Molding Overseas Company in USA

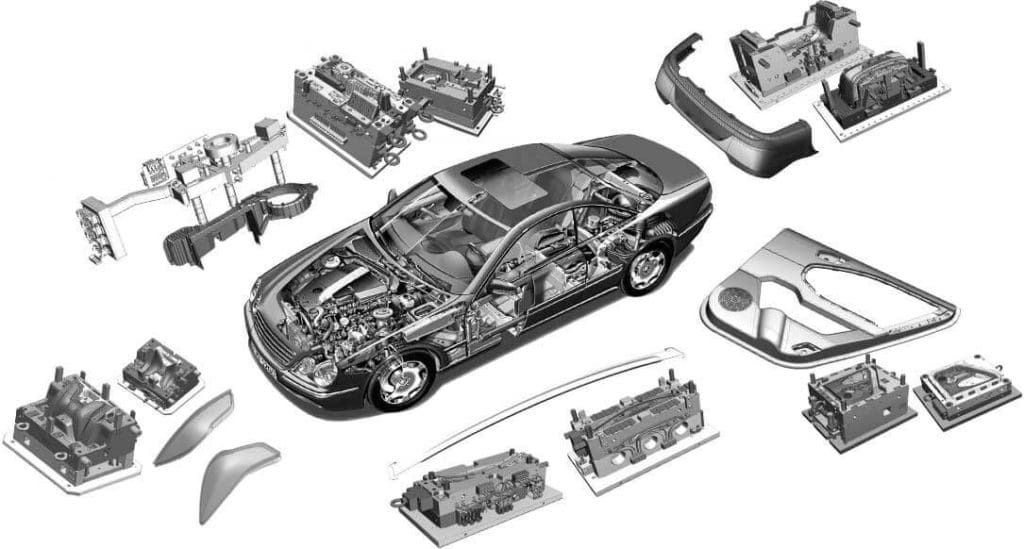

- Tru Mould is a top-tier Automotive Injection Molding Overseas Company, serving the USA and India with excellence in precision and quality solutions.

- TruMould is your trusted partner in automotive injection molding, delivering high-quality, precision-engineered components that drive innovation in the automotive industry. With years of experience and cutting-edge technology, we are committed to helping automotive manufacturers meet the demands of today’s competitive market. Explore our automotive injection molding solutions to discover how we can elevate your production processes and product quality.

Precision and Consistency

Precision and Consistency Cost-Effectiveness

Cost-Effectiveness Design Freedom

Design Freedom