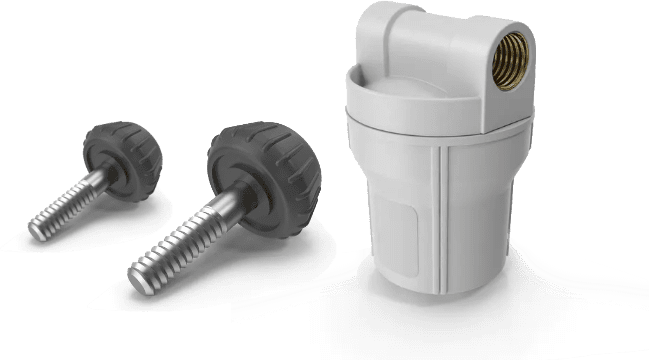

For The Complex Components

Insert

Molding

Trumould is an insert molding overseas company located in the USA, has set itself apart as a trusted partner for businesses seeking high-quality, cost-effective insert molded components. With production facilities in India and a commitment to quality, innovation, and customer satisfaction, TruMould.com is your go-to solution for insert molding needs. Discover the difference that TruMould.com can make in your manufacturing process and experience excellence in insert molding like never before.