Injection Moulding Part Costs

Among various manufacturing processes in the plastics industry, injection molding stands out as a highly favored method. Its efficiency, repeatability, and precision in creating parts to fit within strict tolerances make it a go-to option for the mass production of plastic components. Everyday objects that we come into contact with, like the TV remote in your hand or the protective housing of your fan, are just a few examples of items that are brought to life through the power of injection molding.

The injection molding industry, despite its pivotal role in our daily lives, is not without its challenges. One of the primary difficulties lies in the lack of injection moulding costs standardization. This void leads to a broad spectrum of quotes given by injection molding vendors to manufacturers, leaving the latter in a quandary about the appropriate amount they should be budgeting for their desired products.

In response to this issue, we at Trumould are spearheading an initiative aimed at eliminating this uncertainty from the quotation process. Our belief is rooted in the premise that a designer should not have to wait anywhere between 5 to 10 days to receive a quote from a vendor. Instead, we argue that there should be a well-defined, systematic approach in place to calculate costs, thus enabling designers to predict what the expenses should be and adjust their designs accordingly.

As a testament to our commitment to this cause, we have created Trumould’s Auto Quoting Engine. This unique solution is geared towards not only making procurement more efficient but also revolutionizing the entire injection moulding costs estimation process.

The Emergence of On-Demand Injection Molding

On-demand injection molding is gaining popularity due to shifting consumer preferences and a volatile market landscape. Modern customers increasingly prefer personalized products, and markets now demand quicker, more flexible production methods. On-demand manufacturing supports these needs by enabling fast adjustments and shorter lead times.

Digitalization has further accelerated this shift. With online platforms, companies can upload design files, receive instant quotes, and place orders seamlessly. This digital process drastically shortens lead times compared to traditional methods. At Trumould, we’re leading this transformation through our tech-enabled platform that directly addresses cost-related challenges in injection molding.

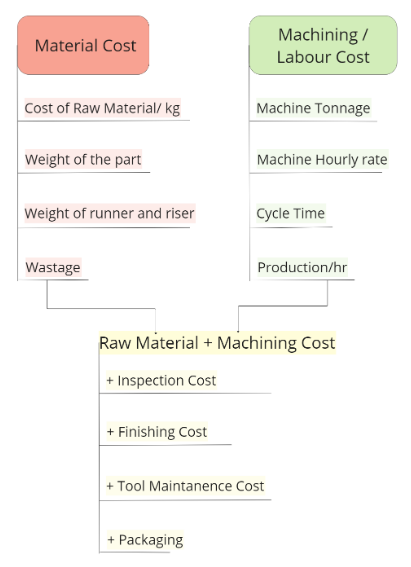

Material Cost

Raw Material Cost

Injection molding offers access to over a thousand plastic materials, each with varying prices. Material choice significantly affects the final cost. At Trumould, we guide clients in selecting plastics that meet performance requirements without overshooting their budgets. Given the material cost fluctuations over the last 3–4 years, it’s often the most volatile component of the total cost.

Part Weight

The volume of the molded part plays a key role in cost. While designers have limited influence over function-driven weight, we generally advise using thinner walls to reduce material usage, unless structural integrity demands otherwise.

Runner and Riser Weight

In high-volume production, even small additions like runners and risers impact cost. To address this, we recommend hot runner systems when production volume justifies the investment. Our in-house system calculates runner weight based on part geometry and gate location, helping optimize material use.

Wastage

Material wastage mainly occurs during production changeovers, especially when switching between plastic types. Clearing the previous material requires purging, which leads to waste. Additional losses may arise from machine faults, human error, or poor-quality plastic batches.

Labour Cost

Machine Tonnage

The machine’s tonnage directly affects cost. Higher tonnage machines needed for complex or large parts incur more operating expenses due to increased energy use, space requirements, and maintenance.

Machine Hourly Rate

Injection molding involves a team of professionals—programmers set process parameters, production managers optimize machine use, and operators ensure smooth runs. In addition to labor, machine operation costs add to the total hourly rate. Trumould standardizes these rates based on tonnage, feeding data into our Auto Quoting Engine to help designers accurately estimate part prices.

Cycle Time

Cycle time covers the complete molding process—from mold closure and cavity fill to cooling and part ejection. Cooling usually takes the most time. We help reduce cycle time by optimizing mold cooling or choosing faster-cooling materials. Our team accurately estimates cooling times using the part’s geometry and plastic properties.

Production Rate

The production rate—the number of parts produced per hour—depends on mold cavities, cycle time, process efficiency, and production volume. Once calculated, machining cost becomes a straightforward equation. Our structured systems predict efficiency with over 90% accuracy, contributing to the effectiveness of our auto quoting tool.

Other Cost Components

Inspection Cost

After molding, each batch undergoes rigorous quality checks. Our trained inspectors check for defects using statistical process control to determine the ideal sample size. Inspection typically accounts for 2–5% of part cost.

Finishing Cost

Some parts require post-processing like trimming runners, tapping, or printing. Since these steps are labor-intensive and difficult to automate, we advise minimizing them. We evaluate finishing costs on a case-by-case basis.

Tool Maintenance

Improper tool care leads to costly repairs and defects. We implement regular maintenance to prevent issues like vent deposits. Trumould spreads maintenance costs across the production volume, usually adding 1–3% to the part cost.

Packaging

Packaging, which makes up about 5% of total cost, includes:

-

Part-Level: Individual wrapping to prevent damage

-

Box-Level: Safe, optimized packing inside cartons

-

Shipment-Level: Palletizing and securing boxes for transit

We standardize these steps unless industry-specific needs require customization.

Trumould Auto Quoting Engine

Trumould with its years of expertise in plastic injection molding domain is able to formalize all these factors and cohesively develop an Auto Quoting Engine. We can quote a injection moulding part costs with seconds using this engine. This not only saves time and hassle but it also helps in benchmarking the cost of the part. Try our auto quoting engine and get part cost instantly, you can also turn the knobs by switching around the materials, quantity and finishes.