Product Design and Prototyping

We kickstart the process by understanding your product requirements and creating a precise 3D design.

TruMould redefines plastic injection molding. Say goodbye to waiting and guesswork; experience the future with our Auto Quoting Engine.

The Injection Mold Journey

We kickstart the process by understanding your product requirements and creating a precise 3D design.

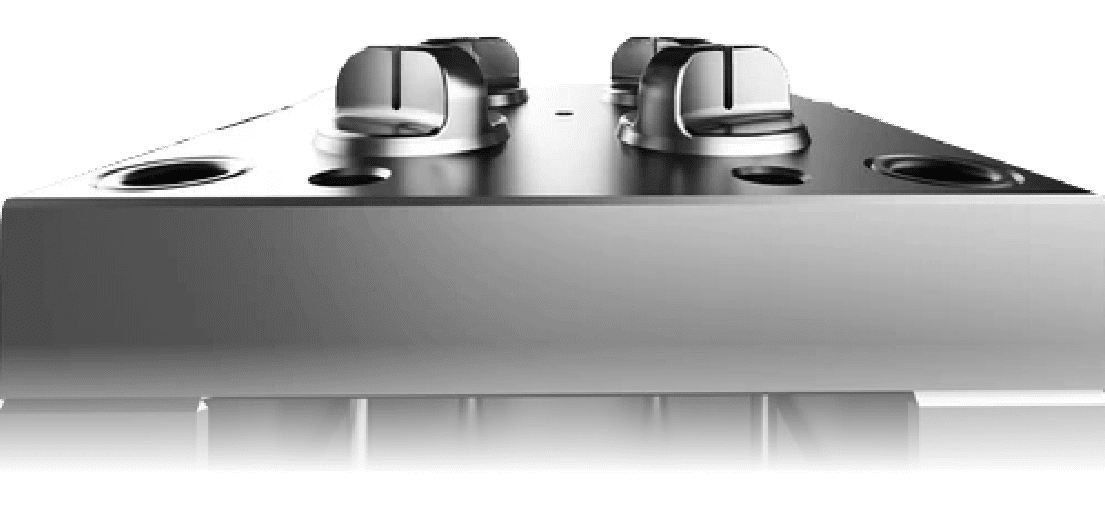

After design approval, our engineers craft precision molds using selected materials.

Plastic material is melted and injected into the mold cavity, creating the desired shape.

Our rigorous quality control includes dimensional checks, visuals inspections, and performance assessments to meet specifications

Once quality checks are passed, finishing operations are performed followed by careful packaging for shipment.

Get started with only 100 parts. No need to commit to large quantities, making it cost-effective for projects of all sizes.

Access a vast material selection of over 1000 options, paired with expert design support for injection moldable parts.

We’ve innovated mold production to offer quality molds at lower costs, ensuring affordability without compromising on quality.

With a 20-day delivery timeframe, our instant quotes and protomolds accelerate the process, swiftly delivering.

We support you all the way from product development to delivering quality products to your customers

We are the world’s fastest digital manufacturing source for rapid prototypes and on-demand Injection Molded parts. Our automated quoting and manufacturing systems allow us to produce commercial-grade plastic, rubber parts within days. A manufacturing partner that helps you accelerate speed to market and strategically manage demand volatility across the entire product life cycle.

Know More

Once the design is approved, our engineers develop the mold design. The mold’s material is selected based on the type of plastic and the desired characteristics of the finished product. Our advanced machinery is used to manufacture the molds with high precision.

Know More

Mold manufacturing involves creating precise, custom molds for various industries. Our skilled team utilizes advanced CNC machining and 3D printing to produce high-quality molds that meet your exact specifications. We prioritize precision, durability, and efficiency in every mold we create.

Know More

Plastic parts manufacturing is a highly specialized process where raw plastic materials are transformed into a wide range of components. Our state-of-the-art facilities and experienced team excel in injection molding, extrusion, and thermoforming, ensuring cost-effective production while maintaining strict quality standards. We deliver top-notch plastic parts for diverse applications.

Know More

Contract manufacturing provides a cost-effective solution for outsourcing production. Our company offers comprehensive contract manufacturing services, including design, prototyping, production, and quality control. We have the expertise and resources to handle various industries, ensuring timely and efficient delivery of your products to your specifications.

Know More

info@trumould.com

info@trumould.com  +1 (720) 519-7806

+1 (720) 519-7806  Plot No.67, Rajasthani

Udyog Nagar, GT Karnal Road

Delhi – 110033

Plot No.67, Rajasthani

Udyog Nagar, GT Karnal Road

Delhi – 110033 We at Tru Mould believe that your mold is an Asset. You’re investing in a mini-machine to earn profits from it. The ownership of Production mold or series tooling belongs to you. In the case of production tooling the ownership rests with you, however, a request is sent to ship the mold.

Every Client is shared with a customized mold manual for the tooling which gets developed. This mold manual consists of Various certificates like

There are several surface finish options we provide for custom parts, there are 12 standard plastic surface finish types, and these finishes are divided into four different categories, ranging from smooth finishes to rougher ones, and they are glossy, semi-glossy, matte, and textured injection molding surface finish.

Yes, we run the mold for you which is generally termed On-demand Manufacturing. We have all sizes of machines starting from 25 Tons up to 3000 Tons. We can produce starting from Few Grams to 15 Kilograms. There is no MOQ (Minimum Order Quantity) so you do not have to carry excess inventory. Trumould offers Lead times as low as 3 days to start your production.

We offer you a wide variety of materials to choose from. And they are ABS, acrylic, HDPE, industrial peek, LDPE, nylon 6 / PA 6, nylon 66 / nylon 6/6, PBT, PC (Polycarbonate), PC-ABS polycarbonate, PC-ABT, PEI ( Ultem), PET, PLA, Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), POM/ Delrin acetal, PPE-PS, PPS, PSU, PVC, TPE (elastomer), and TPV (rubber).