Introduction

Injection molding is a widely used manufacturing process for producing plastic parts in high volumes with precision and consistency. It is a versatile and efficient process that offers many advantages over traditional manufacturing methods.

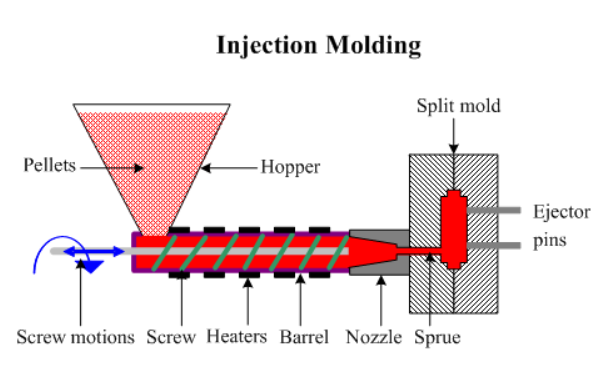

The injection molding process begins by designing a custom mold that matches the desired part’s shape and specifications. The mold is then fitted into an injection molding machine, where the plastic pellets are melted and injected into the mold under high pressure. The plastic then cools and solidifies within the mold, creating the finished product.