What is Injection Molding Process?

Introduction

Injection molding is a widely used manufacturing process for producing plastic parts in high volumes with precision and consistency. It is a versatile and efficient process that offers many advantages over traditional manufacturing methods.

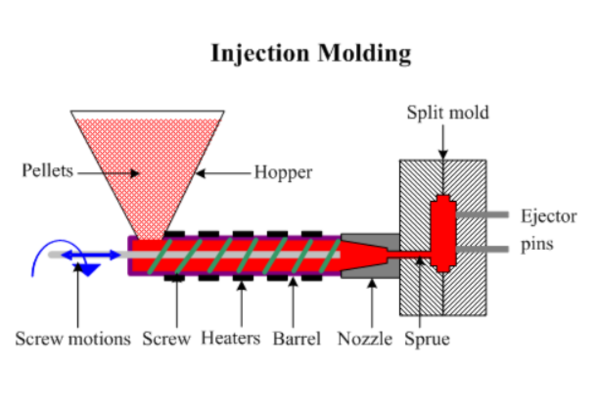

The injection molding process begins by designing a custom mold that matches the desired part’s shape and specifications. The mold is then fitted into an injection molding machine, where the plastic pellets are melted and injected into the mold under high pressure. The plastic then cools and solidifies within the mold, creating the finished product.

Injection Molding process

When to use Injection Molding ?

Injection molding is ideal for producing high volumes of parts with complex geometries, tight tolerances, and consistent quality. It is particularly useful for producing large quantities of identical parts, making it an ideal process for mass production.Other benefits of injection molding include:

- The ability to use wide range of plastic materials

- High levels of precision and accuracy

- Excellent surface finish and detail

- Low labour costs

- Reduced scrap rates

When Not to Use Injection Molding ?

While injection molding is an excellent choice for many applications, there are instances where it may not be the best option. For example, injection molding may not be suitable for producing small quantities of parts or for prototypes that require quick turnaround times. Other reasons why injection molding may not be the best option include:

- High upfront costs for tooling and mold design

- Difficulty in producing certain shapes or features

- Unsuitable for materials with poor flow characteristics.

Conclusion

Injection molding is a versatile and efficient process that provides high-quality plastic parts with excellent accuracy and consistency. By leveraging the benefits of injection molding, manufacturers can produce high volumes of parts with tight tolerances, complex geometries, and excellent surface finishes. However, injection molding may not be suitable for every application, and manufacturers must consider factors such as volume, complexity, and material selection when deciding whether to use injection molding for their production needs. Trumould is trying to revolutionalize this manufacturing process by utilizing state of the art technology to deliver value to customer. We have built an online quoting system that provides instant quote to our customers thereby cutting the lead time by 5-10 days.

Categories

Recent Posts

Contact Us

Error: Contact form not found.